|

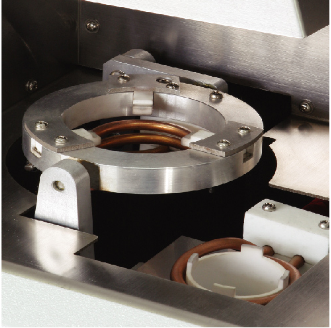

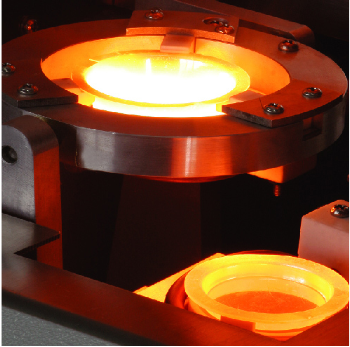

High-Frequency Induction Fusion System |

|

|

|

|

|

Model:

FFV 2D

FFV 2D+

FFV 4D

FFV 4D+

FFV 8C

Features:

● Quick sample preparation, 6-10 minutes for every sample preparation including cooling time.

● Moulding method to lower crucible cost.

● Manual or automatic moulding can be selected by customers.

● Automatic moulding can decrease interference.

● Shaking and pouring can let sample mix completely.

● Applying PLC controller with life more than 100000 hours.

● Touch-screen is easy for operation.

● Safe operation with exhaust system.

● Without preheating or keeping temperature.

●Real-time infrared temperature measurement.

Indicators

Model

|

Sample No.

|

Moulding mode

|

Dimensions (mm)

|

Power

|

Weight

|

FFV2D

|

1

|

Manual- moulding mode

Single-crucible & single-mould

|

660X700X530

|

4KW

|

40Kg

|

FFV2D+

|

1

|

Automatic- moulding mode

Single-crucible & single-mould

|

660X700X530

|

4KW

|

40Kg

|

FFV4D

|

2

|

Manual- moulding mode

Double-crucible & double-mould

|

660X700X530

|

6KW

|

40Kg

|

FFV4D+

|

4

|

Automatic- moulding mode

Double-crucible & double-mould

|

780X760X580

|

6KW

|

60Kg

|

FFV8C

|

4

|

Automatic- crucible bottom moulding

|

780X760X580

|

4KW

|

60Kg

|

Sample treatment:

● Oxide

● Cement, carbonate, silicate, ceramics, furnace blast, glass, sand

● Geological samples

● Sulfide

● Bauxite, fluoride

● Catalyst

Pure metal, ferroalloys and other alloys

Model:FF V2D / FFV2D+ |

FFV2D / FFV2D+ Fusion System |

Features:

● Quick sample preparation, 6-10 minutes for every sample preparation including cooling time.

● Moulding method to lower crucible cost.

● Manual or automatic moulding can be selected by customers.

● Automatic moulding can decrease interference.

● Shaking and pouring can let sample mix completely.

● Applying PLC controller with life more than 100000 hours.

● Touch-screen is easy for operation.

● Safe operation with exhaust system.

● Without preheating or keeping temperature.

● Real-time infrared temperature measurement.

|

Technical Specifications:

| Model | Sample No.

|

Moulding mode | Dimensions |

| FFV2D | 1 | Manual moulding mode Single-crucible & single-mould |

660x700x530mm |

| FFV2D+ | 1 | Automatic moulding mode Single-crucible & single-mould |

660x700x530mm |

|

● Sample preparation speed: 6-10 minutes for every sample, one every time, manual moulding or automatic moulding.

●Temperature raising speed: to arrive about 1000℃ within 30-60 seconds.

●Temperature range: 0-1300℃ (highest temperature is preset).

●Mixing method: shaking+pouring. Shaking angle is adjustable from 0 to 30o.

●Operation method: with PLC controller. Some fusion methods are preset according to customers’ requirements before leaving factory. Max. ●20 sample programs can be stored.

●Cooling mode: normal cooling and wind cooling.

●Safety protection: over-pressure, over-current, over-heat and lack-water alarm.

●Heating mode: high-frequency induction heating.

●Shaking frequency: 50Hz-80Hz

●Input voltage: single phase 180-245V, 50-60Hz, input current: 15A

●Dimensions: 660x700x530mm

●Gross weight: 40Kg

|

Sample treatment:

● Oxide

● Cement, carbonate, silicate, ceramics, furnace blast, glass, sand

● Geological samples

● Sulfide

● Bauxite, fluoride

● Catalyst

● Pure metal, ferroalloys and other alloys

Model: FFV4D / FFV4D+ |

FFV4D / FFV4D+ Fusion System |

Features:

● Quick sample preparation, 6-10 minutes for every sample preparation including cooling time.

● For larger quantities of sample preparation.

● Shaking, self-rotation and pouring can let sample mix completely.

● Moulding method to lower crucible cost.

● Manual or automatic moulding can be selected by customers.

● Automatic moulding can decrease interference.

● Applying PLC controller with life more than 100000 hours.

● Touch-screen is easy for operation. Sample preparation procedures and parameters can be set easily.

● Safe operation with exhaust system.

● Without preheating.

● Real-time infrared temperature measurement.

|

Technical Specifications:

| Model | Sample No.

|

Moulding mode | Dimensions |

| FFV4D | 2 | Manual moulding mode Double-crucible & double-mould |

660x700x530mm |

| FFV4D+ | 2 | Automatic moulding mode

Double-crucible & double-mould

|

720x780x580mm |

|

●Temperature raising speed: to arrive about 1000℃ within 30-60 seconds.

●Temperature range: 0-1300℃ (highest temperature is preset).

●Mixing method: shaking+self-rotation+pouring. Shaking angle is adjustable from 0 to 30o.

●Operation method: with PLC controller. Some fusion methods are preset according to customers’ requirements before leaving factory. Max. 20 sample programs can be stored.

●Cooling mode: normal cooling and wind cooling is helpful to get good shaping.

●Safety protection: over-pressure, over-current, over-heat and lack-water alarm.

●Heating mode: high-frequency induction heating.

●Shaking frequency: 50Hz-80Hz

●Input voltage: single phase 180-245V / Three-phase 342-418V, 50-60Hz, input current: 30A/20A

●Dimensions: 660x700x530mm OR 720X780X580MM

●Gross weight: 40Kg OR 60Kg

|

Sample treatment:

●Oxide

●Cement, carbonate, silicate, ceramics, furnace blast, glass, sand

●Geological samples

●Sulfide

●Bauxite, fluoride

●Catalyst

●Pure metal, ferroalloys and other alloys

| Model: FFV8C |

FFV8C Fusion System |

Features:

● Quick sample preparation, 6-10 minutes for every sample preparation including cooling time.

●For larger quantities of sample preparation. 4 samples every time.

●Can run for 24 hours without break.

●Automatic crucible bottom moulding to raise sample preparation efficiency.

●Shaking and self-rotation can let sample mix completely.

●Applying PLC controller with life more than 100000 hours.

●Touch-screen is easy for operation. Sample preparation parameters can be set or changed easily.

●Safe operation with exhaust system.

●Without preheating.

●Real-time infrared temperature measurement.

|

Technical Specifications:

| Model | Sample No.

|

Moulding mode | Dimensions |

| FFV8C | 4 | Automatic crucible bottom moulding | 720x780x580mm |

|

●Temperature raising speed: to arrive about 1000℃ within 30-60 seconds.

●Temperature range: 0-1300℃ (highest temperature is preset).

●Mixing method: shaking+self-rotation. Shaking angle is adjustable from 0 to 30o.

●Operation method: with PLC controller. 7 fusion methods are preset before leaving factory. Max. 20 sample programs can be stored.

●Cooling mode: normal cooling and wind cooling.

●Safety protection: over-pressure, over-current, over-heat and lack-water alarm.

●Heating mode: high-frequency induction heating.

●Shaking frequency: 50Hz-80Hz

●Input voltage: Three-phase 342-418V, 50-60Hz, input current: 10A

●Dimensions: 720X780X580MM

●Gross weight: 60Kg

|

Sample treatment:

●Oxide

●Cement, carbonate, silicate, ceramics, furnace blast, glass, sand

●Geological samples

●Sulfide

●Bauxite, fluoride

●Catalyst

●Pure metal, ferroalloys and other alloys