| Grinding mill

|

¢ñ.Grinding vessel cubage: 100cc/ set FFGM¡ª1¡ªT FFGM¡ª1¡ªT FFGM¡ª1 ¡ªPS FFGM¡ª4¡ªPS ¢ò.Grinding vessel cubage: 50cc/ set FFGM-50 ¢ó©qAccessories Grinding vessel: Tungsten Carbide Chrome-Steel |

Grinding vessel cubage: 100cc/ set

FFGM series Grinding mill has provided for XRD.

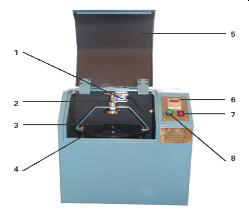

FFGM series Grinding mil uses the suspension fork structure (FFGM-1: 6 pieces press springs, 8 pieces pull springs; FFGM-4: 8 pieces press springs£¬8 pieces pull springs.). Causes the Grinding mill to grinding efficiency enhancement, the noise reduces. Suspension fork structure: Increases the horizontal direction action, enhances the grinding efficiency; reduces the vertical horizontal direction action, reduces the mechanical noise. Automatically protection: The Grinding mill will stop automatically under following conditions: ¢Ù Power supply lack 1-phase, or current overload. ¢Ú The cover does not keep in place. Grinding vessel cubage: 100cc/ set

Indicators

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1¡¢ Protection switch |

|

9¡¢ Grinding case

|

Operating Instructions

1. Holding Sample

1.1 Put impact rammer into the grinding case, and then put sample between grinding case and impact rammer.

1.2. Quantity of sample in grinding case shall be 5¡«15cm3.

In case quantity of sample put into the grinding case is ¡Ü5cm3, it may damage the grinding case.

2. Time Setting

2.1. Press two buttons at upper and lower rows on the Time Relay, set the running time, of which the middle digit indicates time units: hour (H), minutes (M), and seconds (S).

2.2. Generally set within 3 minutes for grinding case of tungsten carbide, 10 minutes for that of high chrome.

3. Specimen Preparation

3.1. Put the grinding case on the fixed disk of Vibration Grinding Mill, screw the fixed handle. See Fig.2. Fasten down the cover of Vibration Grinding Mill, press green start button of it. Start Vibration Grinding Mill.

3.2. If something unexpected happened, please press red emergency stop button immediately. Do not open the cover of Vibration Grinding Mill before the machine completely stopped.

3.3. After the machine completely stopped, open the cover of Vibration Grinding Mill, take out the grinding case. Pour sample into filter sieve, particle size of 80% sample should be in ¡Ü80um.

3.4. In case the sample after grinded can¡¯t reach the requirement described in Item 3.3, take out the grinding case, cool it to less than 60¡æ in room temperature, and work continuously. Find out optimum grinding time.

Accessories

|